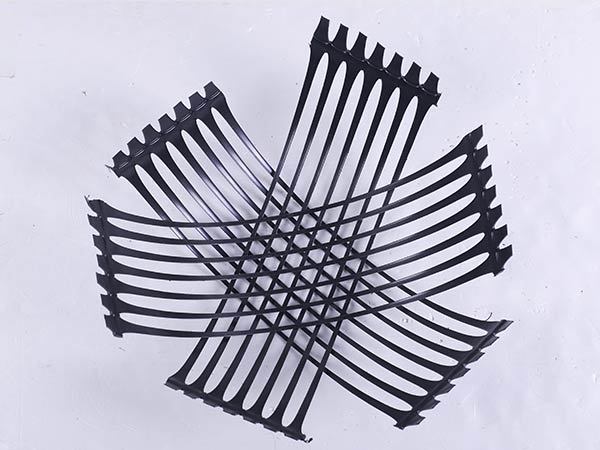

The role of steel-plastic geogrid

Lightweight and flexibility:

The steel and plastic grille is lightweight (about 0.5-2kg/m²), easy to carry and lay, can be constructed manually or mechanically, shortening the construction period.

Economy:

Compared with pure steel stretching or concrete structures, the material cost and construction cost of steel-plastic gratings are lower, and there is no need for complex anti-corrosion treatment, and the comprehensive cost-effectiveness is high.

2025-05-28

One-way plastic geogrid support structure and slope engineering

Solution Design:

Multi-layer grids are laid along the slope of the crack surface, with a layer spacing of 0.2m, a strength of ≥100kN/m, and both ends are anchored to the stable formation ≥2m.

In conjunction with the drainage blind ditch, reduce the adverse impact of pore water pressure on the grid.

2025-05-28

Generate one-way plastic geogrid engineering application scenarios and design

Main criteria:

"Technical Specifications for Application of Highway Geosynthesis Materials" (JTG/T D32)

"Railway Subgrade Design Code" (TB 10001)

"Technical Specifications for the Application of Geosynthetic Materials" (GB/T 50290)

2025-05-28

Fiberglass geogrid technology and material characteristics

Application cases of corrosion resistance in special geology

Comparison of life of road use grilles in coastal saline soil areas

Verification of corrosion resistance of grilles in acidic soil environment

2025-05-28

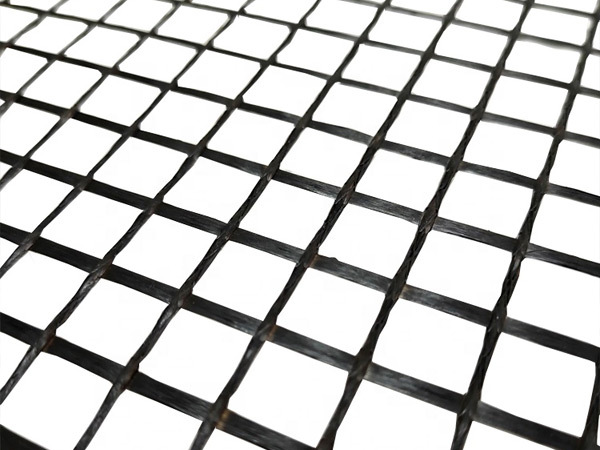

Advantages of fiberglass geogrid

When laying, avoid overstretching or folding to ensure that the grille is flat and wrinkle-free.

During construction, asphalt or soil layer should be covered in time to avoid performance degradation due to long-term exposure.

2025-05-28